Seamless working with ERP Software

- Pushkaraj G. Natu

ERP system is chain of transactions wherein each activity is dependent on the other. ‘Material Code’ connects all these activities together. In every transaction, actions are expected related to specified material code and these codes are most critical aspect of any ERP system. An error in preparation of material code may lead to ERP failure.

In project engineering companies, material code plays vital role in functioning of ERP system. Variety of code is always on higher side in any project engineering firm as company supplies end-to-end solution to the customer. Therefore, code handling becomes critical and tedious in project engineering organizations.

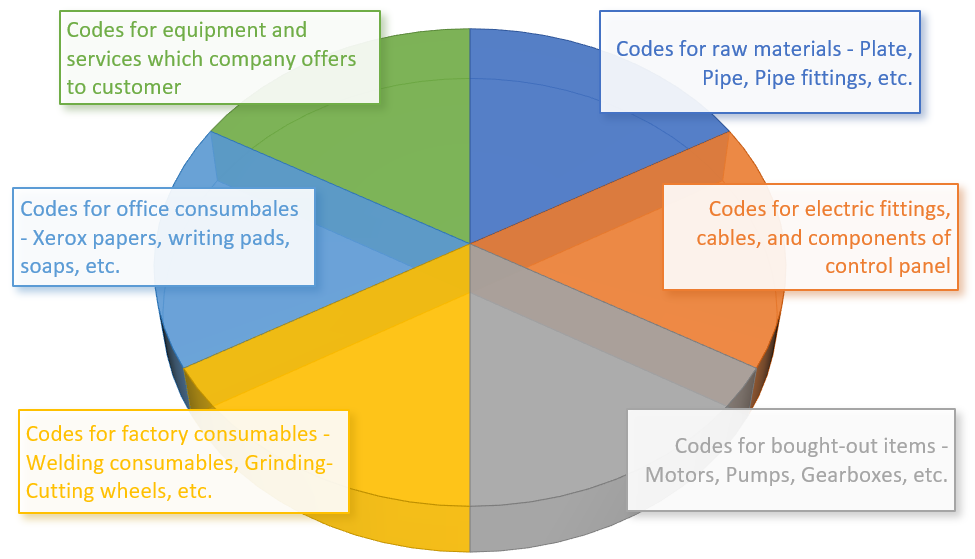

Broad categories of material codes required in any project engineering companies are as below:

Steps to establish material master in your organization are as below:

a. Identify material types

- Identify material types based on its nature, price, specification length, importance in process, etc.

- It will give different aspects of materials and based on the same, an industry may define their material code master.

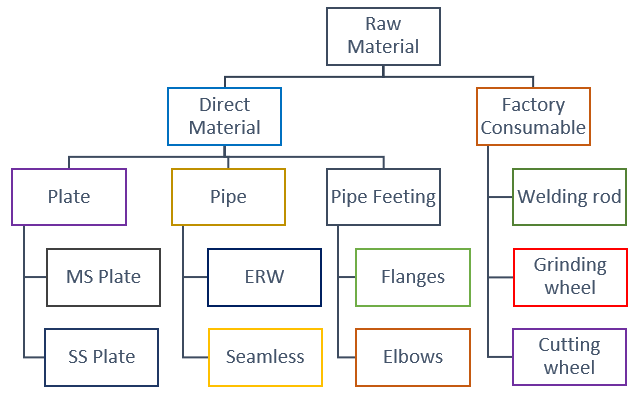

b. Create groups and sub-groups

- Materials must be categorized in groups and sub-groups to make material identification and handling easy.

- Refer below example of raw material master for understanding group and subgroup concept

c. Add various tags in material master

- Tags like material category based on A-B-C analysis, Material location, Buyer name or buyer group, etc.

- It helps in analysis of material dump in future.

d. Create simple coding logic

- Do not create fancy logic which will try to decode material properties, material name, material group, etc.

- Adding logic to the code to make it identifiable goes in wrong direction or it fails in serve the purpose in most of the cases. Simple reason because of quantum of material variety getting handled in project engineering companies.

- Simple 7 or 8-digit numerical code serves the purpose.

- Same length code makes report reading easy.

e. Define material descriptions for categories

- Material description is a string, which gives unique identification of material.

- Every material description in system must be unique.

- ERP system may identify the duplication of descriptions if those are written in particular fashion with set logic.

- Code description must cover specifications of material. It must be specified in engineering language which everyone can understand during supply chain management.

- Ex. ‘FLANGE-SORF-SA240F304-15NB-#150’

Drop your comment